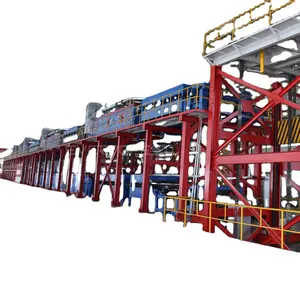

Aluminum coil coating line is a continuous process for coating aluminum coils with a uniform and even layer of paint. This process is essential in manufacturing various aluminum products, such as building materials, consumer goods, and appliances, as it protects against corrosion and enhances the appearance and durability of the final product. The aluminum coil coating line operates by first cleaning and pretreating the aluminum coils, then applying the desired coating using advanced machinery. A curing process follows this to ensure the paint adheres properly to the coil's surface.

Maintaining a Prepainted Aluminum Coil Line

To ensure that the coated aluminium coil line operates at its maximum potential, perform regular maintenance.

Several factors can impact the performance of a coated aluminum coil line, including wear and tear on mechanical components, build-up of coatings or debris, and improper adjustments. By regularly inspecting and servicing the line, one can address these issues before they cause significant problems. This process not only extends the life of the line but also ensures that it is running at optimal efficiency, producing consistent and high-quality results.

Additionally, regularly maintaining the pre-painted or painted aluminum coil line can improve safety conditions for employees and reduce the risk of accidents or downtime. Doing so can help minimize production costs and keep the line running smoothly, helping to ensure the success of the business.

An Overview of the Different Types of Coated Aluminium Coil

Liquid paint is the most common type of coating. It is applied using a roll coating process and can be made in various colors and finishes. The liquid paint is applied to the metal surface in a thin, even layer and cured to create a durable and attractive finish, making a pre-painted aluminium coil.

Powder coating involves the application of dry powder material to the metal surface. The powder is electrostatically charged and then cured in an oven to create a durable and attractive finish. This type of coating is known for its superior durability and resistance to chipping, fading, and scratching.

Plastisol refers to a type of vinyl-based solution applied to produce coated aluminium coils. It is commonly used for metal roofing and siding applications because of its ability to bond well to metal surfaces and provide a weather-resistant finish. Plastisol is also highly flexible, making it ideal for curved or coil-coated aluminum sheet.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4