Exploring Aluminum Profile Bending Machines

Aluminum profile bending machines are specialized equipment crafted to mold aluminum profiles into curves, arches, and other intricate forms. They play a pivotal role in sectors like construction, automotive, and aerospace, where curved aluminum profiles are integral in crafting doors, windows, and architectural components. The bending process can be categorized as hot or cold; hot bending is preferred for larger or thicker profiles, while cold bending is more suited for thinner or smaller aluminum materials.

The underlying principle of these machines is straightforward: they exert controlled pressure or heat on aluminum profiles, causing them to plastically deform. In hot bending, the aluminum profile is heated above its specific annealing point, allowing it to bend without fracturing. Conversely, cold bending is conducted at room temperature and is commonly utilized for smaller profiles or when precise angles are imperative. These machines can be operated manually or via computer numerical control (CNC) for intricate bending tasks.

Essential for businesses necessitating precise and consistent aluminum profile bending, these machines ensure high-quality production while prioritizing operator safety and material integrity during the bending process. Equipped with adjustable heating temperatures, pressure control systems, and interchangeable parts, these machines offer efficiency and adaptability for diverse bending needs.

Varieties of Aluminum Profile Bending Machines

Aluminum profile bending machines are available in various types to accommodate different needs and applications:

-

Manual Benders: Suited for small projects or occasional usage, manual benders are hand-operated tools known for their versatility, portability, and user-friendliness. They are commonly employed for thin-walled profiles that do not necessitate high shaping force.

-

Hydraulic Benders: Designed for heavy-duty tasks, hydraulic benders can exert substantial pressure to bend thick-walled or high-strength aluminum profiles. They are prevalent in large manufacturing facilities and the construction sector.

-

CNC Bending Machines: Tailored for high-volume production or intricate shapes, CNC bending machines offer precision, speed, and consistency. Programmable for various profiles, they excel in industrial settings.

-

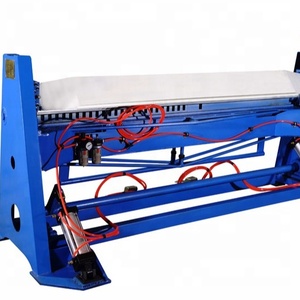

Roll Benders: Operating by feeding aluminum profiles through a series of rollers, roll benders reduce the force needed to bend them gradually. They are suitable for crafting large curves or coils and are commonly used in signage and roofing industries.

-

Motorized Benders: Similar to manual benders but featuring a motorized drive, these benders reduce physical effort. Ideal for high-volume applications, they significantly save time and labor.

Choosing the Right Aluminum Profile Bending Machine

Selecting the appropriate aluminum profile bending machine requires a thorough evaluation of several factors. Businesses should consider the type and volume of material to be bent, the desired curvature degree, and the machine's operational capacities.

For construction firms or manufacturers engaged in large projects like curtain walls or structural components, opting for highly automated and precise machines such as CNC press brakes or 3/4-axes synchronized bending machines is crucial. These machines ensure both high productivity and consistent results necessary for sizable projects.

Tube fabricators or companies specializing in pipe bending should choose mandrel or roller bending machines based on the need to maintain shape consistency within industry standards. Factors like material diameter and wall thickness should also be taken into account when selecting a machine.

Businesses in advertising or retail may require letter bending machines capable of producing various shapes with different materials to maintain design flexibility and brand consistency across signage and product offerings.

Additionally, considering after-sales support such as video technical assistance or field maintenance services provided by suppliers is vital, particularly for intricate machinery like profile bending machines that may require specialized upkeep.

Lastly, energy efficiency is increasingly significant for cost-effectiveness and environmental concerns. Hence, opting for machines with energy-saving features is advisable.

Aluminum Profile Bending Machines on Alibaba.com

Alibaba.com serves as a prominent marketplace for businesses seeking reliable aluminum profile bending machines catering to diverse industrial applications. Offering a wide range of options from global suppliers, Alibaba.com simplifies the procurement process by providing a platform for comparing models based on crucial specifications like material type, core components, machinery test reports, and key selling points.

By leveraging Alibaba.com's global reach and extensive product listings from verified suppliers, businesses can find machines tailored to their specific requirements, whether bending profiles for automotive purposes or manufacturing industrial components. The user-friendly interface enables buyers to communicate directly with suppliers to effectively discuss customization needs and after-sales service options.

Alibaba.com's commitment to secure transactions is evident through services like Trade Assurance, which secures payments until the completion of delivery. Furthermore, its dedication to supporting small and medium-sized enterprises with online trade solutions underscores its mission to streamline international commerce processes. In essence, when procuring aluminum profile bending machines via Alibaba.com, businesses can anticipate not only variety but also reliability and convenience without compromising on quality.

Frequently Asked Questions about Aluminum Profile Bending Machines

What is the primary advantage of utilizing an aluminum profile bending machine?

Aluminum profile bending machines offer extensive production flexibility, enabling businesses to craft a wide array of customized profiles for diverse applications in construction, manufacturing, and beyond.

How do CNC machines regulate the bending process?

CNC (Computer Numerical Control) machines employ software to precisely manage the bending process, ensuring accurate and uniform bends. This capability allows for the realization of complex and precise designs with minimal setup time.

Can aluminum profile bending machines handle all types of aluminum profiles?

Aluminum profile bending machines are designed to be versatile and can manage a range of profiles. However, ensuring that the specific machine can accommodate the size and material of the profiles intended for bending is essential.

Are multi-function aluminum profile bending machines available?

Indeed, there are multi-function machines capable of performing various bending operations like roll bending, pipe and tube bending, and beading to meet specific production requirements.

What factors should be considered when determining the capacity of an aluminum profile bending machine?

The capacity of an aluminum profile bending machine should align with the size and volume of the profiles requiring bending. Overloading the machine can lead to wear and tear, impacting its longevity and effectiveness.

Is it feasible to bend aluminum profiles without causing surface damage?

With suitable equipment and techniques, it is possible to bend aluminum profiles without causing damage. CNC machines are particularly well-suited for precise bending tasks.

How can one identify the suitable machine type for their business needs?

Business needs are contingent on the types of profiles requiring bending, the material thicknesses being worked with, the workload volume, and the specific features needed such as CNC control or end forming capabilities.

Is specialized tooling necessary for different profiles when using an aluminum profile bending machine?

Absolutely, distinct tooling sets are required for various profile types due to differences in material thicknesses, bending radii, and complexity. Having the appropriate set for the profiles intended for bending is crucial.

What safety precautions should be observed when operating an aluminum profile bending machine?

Operators should undergo training in safe handling practices, wear suitable personal protective equipment (PPE), and adhere to all operating instructions provided by the manufacturer to ensure safety during operations.

Are after-sales services available for aluminum profile bending machines?

After-sales services vary among suppliers but may encompass video technical support, online assistance, field maintenance and repair services, and the availability of engineers to service machinery internationally. Checking the type of support offered before procurement is essential.

How does the material of an aluminum profile influence its bendability?

The material composition of an aluminum profile significantly impacts its bendability. For instance, higher alloy grades tend to be less malleable than pure aluminum due to increased strength but reduced ductility. It is crucial to select a machine capable of handling the specific material intended for work.

Can I customize the shapes of the profiles I bend with my aluminum profile bending machine?

Many suppliers provide customized support such as end forming, roll bending, and beading to create specific shapes or designs. The extent of customization depends on the machine's capabilities and the availability of suitable tooling.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4