The Concept of Aluminum Casting Machines

Aluminum casting machines are specialized equipment tailored for casting aluminum and its alloys. These machines play a pivotal role in manufacturing, enabling the production of a diverse range of intricate aluminum parts used in various products, ranging from automotive components to household goods. The machines operate based on the principles of metal casting, encompassing the steps of melting the metal, pouring it into a mold, and allowing it to solidify into the desired shape.

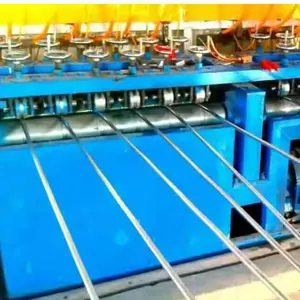

There is a variety of configurations of aluminum casting machines available to meet different casting requirements. These machines are designed to manage varying casting volumes, create different part geometries, and can be equipped with automated controls for precise and consistent output. The essential components of these machines include a furnace, a crucible for melting the metal, and a die or sand mold for shaping the molten metal into the desired form.

The process commences with preparing the aluminum alloy, melting it in the furnace, pouring the molten metal into the crucible for impurity removal to ensure the final product's quality. Once the metal is sufficiently pure and fluid, it is poured into the mold cavity. After the metal cools and solidifies within the mold, the casting is extracted, trimmed, and further processed as necessary.

Varieties of Aluminum Casting Machines

Aluminum casting machines are available in various types to accommodate distinct casting processes and end products. Here are some examples:

-

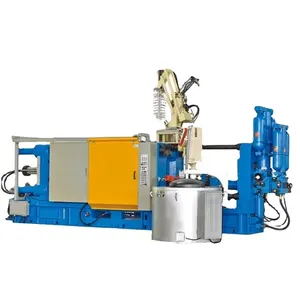

Cold Chamber Die Casting Machine: This type incorporates a cold chamber where molten metal is injected into the mold, suitable for casting alloys with high melting points, commonly used for producing automotive and aerospace components.

-

Hot Chamber Die Casting Machine: In these machines, metal is melted in a crucible and then injected under high pressure into the die, ideal for metals with lower melting points like zinc, magnesium, and other low melting point alloys used for intricate small parts.

-

Vertical Die Casting Machine: Featuring a vertical orientation that leverages gravity in the casting process, this type is typically employed for larger castings such as engine blocks and transmission cases due to its high production capacity.

The selection of each machine type is based on factors like the metal casting volume, part design complexity, and the specific requirements of the end product.

Choosing the Right Aluminum Casting Machine

The selection of the appropriate aluminum casting machine is crucial for businesses engaged in aluminum part production. When contemplating an investment in such a machine, it is essential to evaluate current production needs and future growth prospects. Here are key considerations:

-

Process Compatibility: Determine which aluminum casting process aligns with your production needs, such as die casting or sand casting, each offering unique advantages tailored to specific parts or production volumes.

-

Core Components: Ensure reliability and availability of core components like motors, pumps, PLCs (Programmable Logic Controllers), engines, and bearings. Opt for machines with reputable core components with a proven performance record.

-

Industry Applications: Verify that the chosen machine is suitable for the industries you serve; for instance, a cold chamber die casting machine might be necessary for supplying parts to construction machinery due to its strength and durability.

-

Technical Support and After-Sales Service: Select suppliers offering comprehensive technical and after-sales support, including video technical assistance and field maintenance services, to ensure uninterrupted operations.

Aluminum Casting Machines on Alibaba.com

Alibaba.com serves as a global marketplace connecting businesses with a diverse range of aluminum casting machines tailored to meet various industrial needs. Whether involved in manufacturing plants, construction projects, or retail operations, Alibaba.com provides access to numerous suppliers offering machinery with diverse specifications and capabilities. From precision CNC routers to advanced cold chamber die casting machines, suitable solutions matching specific business requirements can be found.

Alibaba.com streamlines international trade by facilitating communication in local languages and offering services like Trade Assurance, safeguarding payments until delivery confirmation. With over two decades of experience in online wholesale trade solutions, Alibaba.com is synonymous with reliability and efficiency for small and medium-sized businesses aiming to expand operations or streamline supply chains.

By opting for Alibaba.com for aluminum casting machine needs, businesses benefit from a platform emphasizing quality assurance and supplier credibility, directly impacting their bottom line. With a wide range of products catering to diverse casting processes and materials, finding the ideal fit for unique business demands is not only feasible but also facilitated through features supporting convenient mobile purchases and multilingual communication.

Frequently Asked Questions about Aluminum Casting Machines

What is aluminum casting and its applications?

Aluminum casting is a metalworking process involving pouring molten aluminum or its alloys into a mold to create solid forms, widely used in industrial sectors like automotive, aerospace, and machinery manufacturing.

What are the benefits of aluminum casting in manufacturing?

Aluminum casting offers a high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance, making it a preferred choice across various industrial applications.

How does the aluminum casting process function?

The aluminum casting process starts with melting aluminum or its alloys, pouring the molten metal into a mold for solidification, removing the mold after metal cooling, and subjecting the part to necessary finishing processes.

What factors should be evaluated while choosing an aluminum casting machine?

Consider the machine's production capacity, energy consumption, ease of operation, maintenance needs, and compatibility with specific alloy requirements when selecting an aluminum casting machine.

Can aluminum casting be applied in precision machining?

Yes, aluminum casting is suitable for precision machining applications, especially for crafting intricate shapes challenging to achieve through traditional methods.

Are there different types of molds for aluminum casting machines?

Various mold types, such as sand molds, permanent molds, and die casting molds, are utilized in aluminum casting machines based on production needs and desired end products.

What safety precautions are essential during aluminum casting machine operation?

Operators should wear appropriate personal protective gear like safety glasses and gloves and adhere to standard safety protocols for working with metalworking equipment.

How should an aluminum casting machine be maintained?

Regular maintenance of an aluminum casting machine includes cleaning, lubricating moving parts, inspecting mold cavities for wear or damage, and ensuring proper functionality of cooling systems.

What after-sales support is available for aluminum casting machines?

After-sales support for aluminum casting machines may encompass video technical assistance, online support, field maintenance and repair services, and in some cases, overseas service by engineers.

Can a machine handle multiple metal alloys in aluminum casting?

There are multifunctional machines designed to manage various metal alloys; it is crucial to review machine specifications to confirm they meet the requirements for handling specific alloys.

Is customization an option for aluminum casting machines to suit business needs?

Customization is often possible for aluminum casting machines to align with specific business requirements, including tailored mold shapes, sizes, functionalities, and material specifications.

What are the key selling points to emphasize when marketing aluminum casting machines?

When promoting aluminum casting machines, highlight competitive pricing, high productivity, user-friendliness, extended service life, and compliance with industry standards as key selling points.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4