Introduction to 3D CNC Milling Machines

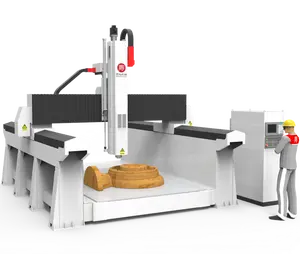

The realm of woodworking and production has been revolutionized by the advent of 3D CNC milling machines. These sophisticated devices are pivotal in shaping and creating intricate designs in wood, offering precision that manual efforts cannot match. The category encompasses a variety of machines tailored for different tasks, from detailed carving to robust cutting.

Types and Applications

The diversity of CNC wood routers caters to a broad spectrum of applications. Industrial-grade CNC routers are the workhorses of high-volume production, essential for manufacturing items like furniture and decorative frames. For more nuanced tasks, such as creating grooves or recesses, plunge routers are the tools of choice, while fixed base routers excel in edge shaping. The versatility of these machines makes them indispensable for tasks ranging from home construction to the creation of complex wooden sculptures.

Features and Materials

A CNC woodworking machine is characterized by its robust construction and the ability to work with various wood types, ensuring durability and adaptability. Features such as power rating, cutting style, and throughput rates are critical, with machines offering a range of specifications to suit different production scales and complexities. The materials used in these machines are selected for their strength and endurance, enabling them to withstand the rigors of continuous operation.

Advantages of CNC Milling in Woodworking

The primary advantage of using a wood CNC machine lies in its precision and efficiency. Automated operations allow for consistent production without the variability that comes with manual routing. This efficiency is not only in terms of time but also in material usage, with advanced software minimizing waste. Furthermore, the ability to program these machines for complex designs enables carpenters and manufacturers to expand their product offerings.

Choosing the Right Machine

Selecting the appropriate 3D CNC router involves considering factors such as the machine's weight, power, and the specific woodworking tasks it needs to perform. The Alibaba platform facilitates this selection process by allowing users to filter through a comprehensive range of options, ensuring that they can find a machine that aligns with their operational requirements without the need to navigate through brand-centric promotions.

Conclusion

In conclusion, the 3D CNC milling machine category on Alibaba.com presents a broad array of options for businesses looking to enhance their woodworking capabilities. With detailed information on each machine's features and capabilities, buyers can make informed decisions to meet their production needs effectively.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4